Ever wondered what is reverse logistics in supply chain management and why it’s gaining so much traction?

In today’s customer-centric world, the journey of a product doesn’t always end with delivery.

Returns, repairs, recycling – these are all vital aspects of a product’s lifecycle, and handling them efficiently is what reverse logistics is all about.

It’s more than just dealing with returns; it’s about optimizing processes to recover value, enhance customer satisfaction, and even contribute to sustainability.

In this post, we’ll dive into the core of reverse logistics in supply chain management and explore the top three strategies that can transform your supply chain from a linear flow to a circular system.

Table of Contents

What is Reverse Logistics in Supply Chain Management?

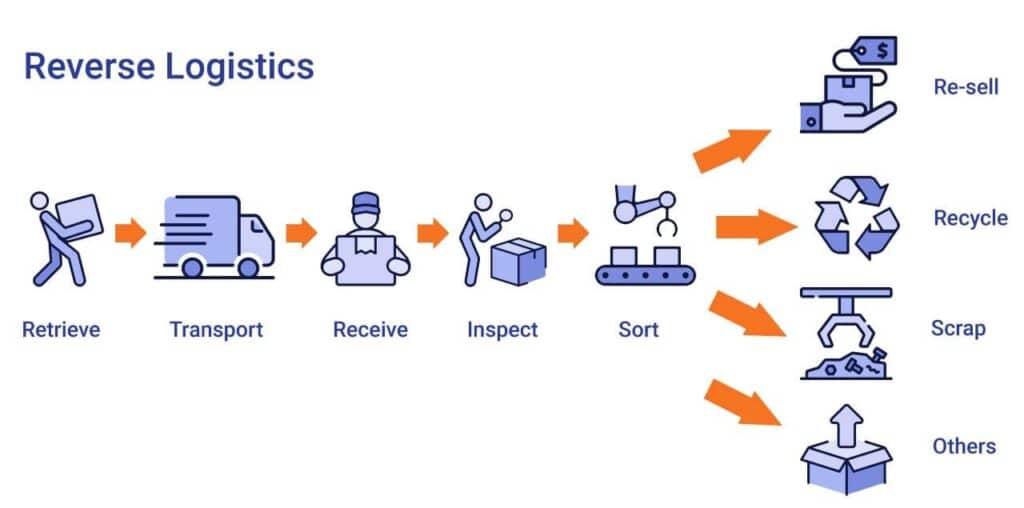

Reverse logistics in supply chain management refers to the process of moving goods from the end consumer back to the seller or manufacturer. It’s essentially the “reverse” of the traditional supply chain flow, which moves products from the manufacturer to the consumer.

The process of planning, implementing, and controlling the efficient, cost-effective flow of raw materials, in-process inventory, finished goods, and related information from the point of consumption to the point of origin for the purpose of recapturing value or proper disposal.

It’s the “backward” flow of goods in the supply chain.

Key Components of Reverse Logistics in SCM:

- Returns Processing: Handling customer returns (defective, unwanted, etc.).

- Refurbishment/Remanufacturing: Repairing or restoring products for resale or reuse.

- Recycling/Material Recovery: Dismantling and processing materials for reuse.

- Waste Disposal: Managing the environmentally sound disposal of unusable items.

- Asset Recovery: Reclaiming and repurposing valuable components.

For more information: Amazon Effect on Supply Chain – A Breakthrough in The World of Supply Chain

3 Key Strategies for Reverse Logistics in SCM

if you’re looking for the top 3 strategies for reverse logistics in supply chain management, here they are:

Strategy 1: Streamlining Return Management for Customer Satisfaction:

This strategy centers on making the return process as easy and transparent as possible for the customer.

It recognizes that a positive return experience can significantly impact customer loyalty and brand perception

Key elements include:

- Clear and Accessible Return Policies: Easy-to-understand policies that clearly outline return procedures, timelines, and eligible products.

- Multiple Return Options: Offering various return methods, such as in-store returns, prepaid shipping labels, and drop-off locations, to accommodate customer preferences.

- Efficient Processing and Communication: Promptly processing returns, providing real-time tracking updates, and offering responsive customer support.

- Automated Return Systems: Implementing online return portals and automated systems to simplify the return process for both customers and businesses.

Customer Impact:

- Reduces customer frustration and enhances satisfaction.

- Builds trust and strengthens customer relationships.

- Encourages repeat purchases and positive word-of-mouth referrals.

Strategy 2: Value Recovery Through Recycling and Refurbishment

This strategy focuses on extracting maximum value from returned products by diverting them from landfills and reintegrating them into the supply chain.

Financial and Sustainability Benefits:

- Reduces waste disposal costs and generates revenue from recycled materials.

- Extends product lifecycles and minimizes the need for new raw materials.

- Enhances brand reputation by demonstrating environmental responsibility.

- Contributes to a circular economy.

Strategy 3: Data-Driven Optimization for Process Efficiency

This strategy leverages data analytics and technology to improve the efficiency and effectiveness of reverse logistics operations.

Role of Data and Technology:

- Provides real-time insights into return volumes, patterns, and costs.

- Enables data-driven decision-making and process optimization.

- Improves inventory management and reduces holding costs.

- Allows for better forecasting, and resource allocation.

In essence, reverse logistics is no longer a peripheral concern; it’s a strategic imperative.

By implementing these top 3 strategies – effective return management, value recovery through refurbishment and recycling, and data-driven process optimization – businesses can turn potential losses into opportunities for growth and customer loyalty.

Learn more: The Power of Global Sourcing in Supply Chain Management

Pros and Cons of Reverse Logistics in Supply Chain Management

Reverse logistics refers to the process of moving goods from their final destination back to the manufacturer or retailer for returns, repairs, recycling, or disposal.

While it plays a crucial role in modern supply chain management, it comes with both advantages and challenges.

Pros of Reverse Logistics in Supply Chain Management

Reverse logistics is essential for a sustainable and customer-centric supply chain, offering cost savings, improved brand reputation, and environmental benefits.

- Cost Savings

- By refurbishing, repairing, or recycling returned products, companies can reduce manufacturing costs and minimize waste.

- Efficient reverse logistics can lower disposal costs and allow businesses to resell or repurpose products.

- Improved Customer Satisfaction

- A seamless return and replacement process enhances customer trust and loyalty.

- Fast refunds and exchanges contribute to a positive brand image and repeat business.

- Sustainability and Environmental Benefits

- Recycling and reusing materials reduce landfill waste and lower the carbon footprint.

- Compliance with environmental regulations helps companies avoid fines and maintain a good reputation.

- Competitive Advantage

- Companies with efficient reverse logistics can differentiate themselves by offering better return policies.

- A well-managed process enhances brand reputation and attracts eco-conscious customers.

- Regulatory Compliance

- Proper disposal and recycling help businesses comply with environmental laws.

- Avoiding illegal waste disposal prevents legal penalties and protects the brand’s reputation.

For more information: Exploring Global Sourcing Advantages and Disadvantages

Cons of Reverse Logistics in Supply Chain Management

Reverse logistics can present challenges such as high costs, operational complexities, and fraud risks.

- High Operational Costs

- Managing returns, transportation, and product refurbishment requires additional resources and investments.

- Costs increase due to the complexity of handling returned or defective goods.

- Complexity in Management

- Tracking returned goods and determining their condition can be challenging.

- A lack of standardized processes can lead to inefficiencies and delays.

- Risk of Fraud and Abuse

- Some customers may exploit return policies by returning used or damaged products fraudulently.

- Managing fraudulent claims adds to operational costs and affects profitability.

- Inventory and Storage Challenges

- Storing returned goods while determining their fate requires extra warehouse space.

- Improper management can lead to overstocking or supply chain disruptions.

- Longer Processing Time

- Assessing, repairing, and reselling returned goods takes time, affecting efficiency.

- Delays in reverse logistics can lead to customer dissatisfaction and increased costs.

Learn more: The Positive and Negative Impacts of the Amazon Effect on Freight in Dubai

Embracing reverse logistics is about more than just handling returns; it’s about building a sustainable and resilient supply chain for the future.

If you’re looking to streamline your reverse logistics processes and transform your supply chain, don’t hesitate to reach out.

Contact Z Line Logistics today, and let us help you optimize your reverse logistics strategy for maximum efficiency and profitability.